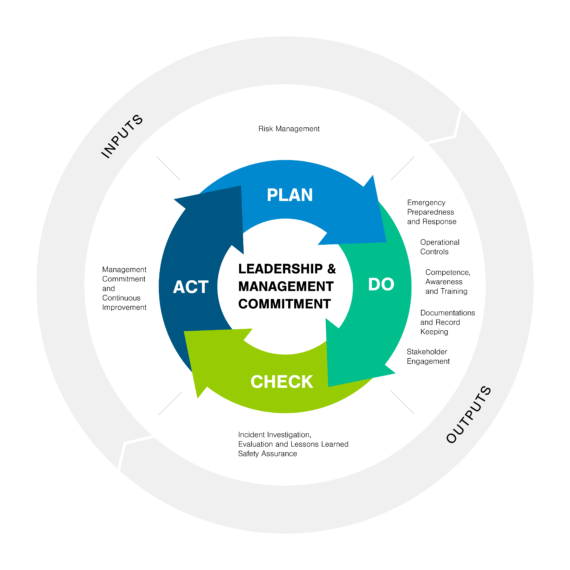

The Pipeline Safety Management Systems (PSMS) Industry Team recently released the 2022 Pipeline SMS Annual Report, reflecting on nearly 85% of the industry implementing a PSMS. The Industry Team serves to facilitate implementation of API Recommended Practice (RP) 1173, Pipeline Safety Management Systems (Pipeline SMS), among the energy pipeline industry and contractor community. Read about operator testimonials and leading implementation practices in the 2022 Annual Report here.